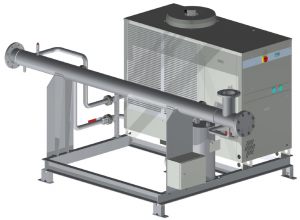

Gas Chill Dryer GCD

Biogas, sewage gas and landfill gas contains not only water vapour but also a whole host of additional impurities such as hydrogen sulphide, NH3 and siloxane, which, when processed in the utilization system can not only lead to a reduction in efficiency, but also result in damage of the system. The dehumidification of the gas before processing is a basic preliminary requirement in order to permit an efficient usage of the biogas and an investment in the sustainability of the utilization system. The gas engines are effectively protected and maintenance requirements considerably reduced. With the ennox gas chill dryer the gas to be processed is passed through a heat exchanger where the cooled gas can expel any moisture which is then collected as condensate.

The condensate can be removed either with a siphon or condensate pump. According to the technical requirements of the installation a post-warming or an economical and ecological energy recovery system can be implemented into the system. The gas chill dryer is available in various sizes and power ratings according to the requirements of the system.

Highlights

• Optimal preparation of the biogas for processing

• Increase in efficiency of the biogas system

• Reduction of maintenance costs for the consumer

• Cost saving and environmental use

• Modular and compact design

• Low pressure drop, optimal specification for the operating conditions

Options

• Condensate removal with pump

• Installation of a post-heater, which uses the heat generated by the engine to heat the cooled gas sinking the relative humidity

• Heat recovery with the use of an integrated heat exchanger – energy saving

• Installation of a pre-cooling for reduction of the energy requirements and operating costs